Benefits

Benefits

Outstanding price-to-performance ratio

Well-thought-out burner design enables the use of various combustion management systems. That makes it possible to meet customers' requirements cost effectively and to offer a system that will be an all-round good investment.

Versatility

The special matching of the flame geometry to the heat generator's combustion chamber is every Weishaupt burner's recipe for success. The combination of electronic compound regulation and the right Mixing assembly allows customised use on different heat generators thermal process plant.

User-friendly concept

All components, such as those for the control of the fuel and air supplies, are clearly arranged and readily accessible.

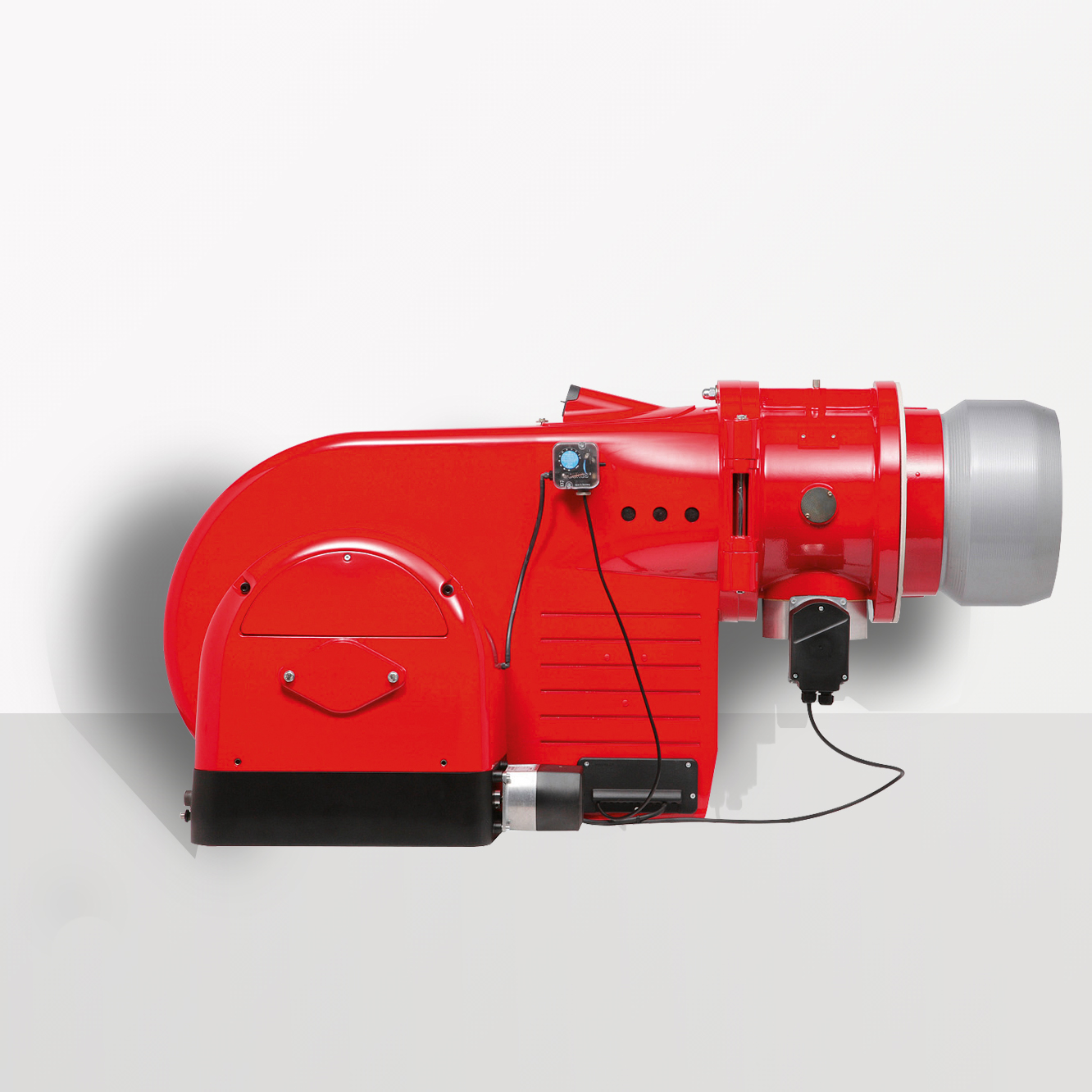

Particularly quiet operation

An innovative fan unit and aerodynamic housing design minimises noise development.

Also suitable for biogenic fuels

Weishaupt oil-firing burners are suitable for Class D and Class A2 gas oil per BS 2869 (fuel oil EL and low-sulphur fuel oil EL per DIN 51603-1), paraffinic oil (fuel oil EL P per DIN/TS 51603-8), and blended gas oil with a biogenic admixture of up to 20.9 % (fuel oil EL A Bio), which can be optionally increased to up to 99.9 %. FAME per EN 14214 can also be used. Hydrogen blends of up to 20 vol% in natural gas are possible for most gas-firing burners, although in some cases an individual approval inspection might be necessary.

Applications

Applications

Simple and universal installation

All electrical components have plug connections. The burners can be hinged open to the left or right-hand side.

Futureproof

The digital combustion management system employed by monarch® burners offers the possibility of communication with other systems, enabling the burner to be integrated with building management and other automation systems. Industry standards, like remote control, monitoring, and fault diagnosis, are well understood by Weishaupt.

Special executions

Weishaupt develops and builds burners for almost all applications – including vertically firing versions.

Technology

Technology

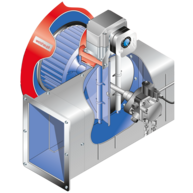

multiflam®

Weishaupt's patented multiflam® technology enables large combustion plant to meet very low emission limits.

Key to the system is a special Mixing assembly that establishes an internal flue gas recirculation. This cools the flame and reduces the formation of nitrogen oxides. The NOx levels that can be achieved are comparable to those of compact burners.

The various Weishaupt burners that are available in multiflam® execution cover a range of capacities extending from 100 kW to 23 000 kW.

Flue gas recirculation

Weishaupt's 4LN-version burners meet the world's most stringent Emissions limits. A 4LN-version burner is equipped with a flue gas recirculation system that has its control components integrated into the burner.

Gaseous Fuels contain almost no sulphur, and so their flue gases mostly comprise Carbon dioxide

(CO₂

), steam (H₂O), and nitrogen (N₂). This is beneficial to the flue gas recirculation, since there is no ash or soot to contaminate the system.

Special adaptations of the Mixing assembly together with the W-FM200 digital Combustion manager

ensure a high degree of flame stability and reliable operational behaviour.

Premix

NOx emission values below 30 mg/kWh are achieved by Weishaupt premix burners.

Premixing followed by surface-stabilised combustion has been state of the art for many years in small condensing boilers. Premix Low-NOx (PLN) burners with NOx Emissions below 30 mg/kWh are the result of further development work at Weishaupt to extend premix technology to burners with larger capacity ranges.

Surface-stabilised combustion relies on a homogeneous gas/air mixture. For that reason, a totally new Mixing assembly was developed for the PLN-version burners. A key feature is the separated gas and air feeds, with the two media not being brought together before the burner tube.

Weishaupt WM-series monarch® burners (55 - 12 000 kW)

| Type | Rating (kW) | |

|---|---|---|

| WM-G10/2 | 85 - 700 |

|

| WM-G10/3 | 130 - 1 050 |

|

| WM-G10/4 | 130 - 1 150 |

|

| WM-G20/2 | 180 - 1 700 |

|

| WM-G20/3 | 250 - 2 500 |

|

| WM-G20/4 | 300 - 3 000 |

|

| WM-G30/1 | 400 - 4 000 |

|

| WM-G30/2 | 550 - 5 000 |

|

| Type | Rating (kW) | |

|---|---|---|

| WM-G20/2 | 200 - 1 450 |

|

| WM-G20/3 | 350 - 2 000 |

|

| WM-G30/1 | 400 - 3 800 |

|

| WM-G30/2 | 500 - 5 000 |

|

| WM-G30/3 | 500 - 5 000 |

|

| WM-G50/0 | 1 000 - 7 500 |

|

| WM-G50/1 | 1 000 - 8 300 |

|

| WM-G50/2 | 1 000 - 11 000 |

|

| Type | Rating (kW) | |

|---|---|---|

| WM-G10/2 | 100 - 600 |

|

| WM-G10/3 | 125 - 900 |

|

| WM-G20/2 | 200 - 1 450 |

|

| WM-G20/3 | 350 - 2 000 |

|

| WM-G30/1 | 400 - 3 500 |

|

| WM-G30/2 | 500 - 4 500 |

|

| WM-G30/3 | 500 - 5 000 |

|

| WM-G50/0 | 750 - 7 000 |

|

| WM-G50/1 | 750 - 7 700 |

|

| WM-G50/2 | 900 - 9 100 |

|

| WM-G50/3 | 900 - 10 000 |

|

| WM-G50/4 | 1 100 - 11 000 |

|

| Type | Rating (kW) | |

|---|---|---|

| WM-G10/1 | 55 - 350 |

|

| WM-G10/2 | 75 - 630 |

|

| WM-G10/3 | 125 - 900 |

|

| WM-G10/4 | 125 - 1 100 |

|

| WM-G20/2 | 250 - 1 600 |

|

| WM-G20/3 | 300 - 2 000 |

|

| WM-G30/1 | 350 - 2 800 |

|

| WM-G30/2 | 400 - 3 800 |

|

| WM-G30/3 | 600 - 5 400 |

|

| WM-G30/4 | 800 - 6 000 |

|

| Type | Rating (kW) | |

|---|---|---|

| WM-G10/1 | 55 - 405 |

|

| WM-G10/2 | 65 - 630 |

|

| WM-G10/3 | 100 - 1 000 |

|

| WM-G10/4 | 110 - 1 250 |

|

| WM-G20/2 | 150 - 2 100 |

|

| WM-G20/3 | 350 - 2 600 |

|

| WM-G30/1 | 350 - 3 100 |

|

| WM-G30/2 | 450 - 4 100 |

|

| WM-G30/3 | 600 - 5 700 |

|

| WM-G30/4 | 600 - 6 200 |

|

| WM-G50/1 | 800 - 8 000 |

|

| WM-G50/2 | 1 000 - 11 000 |

|

| WM-G50/3 | 1 000 - 12 000 |

|

| Type | Rating (kW) | |

|---|---|---|

| WM-G10/1 | 20 - 405 |

|

| WM-G10/2 | 30 - 630 |

|

| WM-G10/3 | 50 - 1 000 |

|

| WM-G10/4 | 60 - 1 250 |

|

| WM-G20/2 | 80 - 2 000 |

|

| Type | Rating (kW) | |

|---|---|---|

| WM-L10/2 | 120 - 600 |

|

| WM-L10/3 | 200 - 900 |

|

| WM-L20/2 | 400 - 1 450 |

|

| WM-L20/3 | 450 - 2 000 |

|

| WM-L20/4 | 350 - 2 450 |

|

| WM-L30/1 | 450 - 3 500 |

|

| WM-L30/2 | 600 - 4 500 |

|

| WM-L30/3 | 600 - 5 000 |

|

| WM-L50/0 | 1 200 - 7 000 |

|

| WM-L50/1 | 1 200 - 7 700 |

|

| WM-L50/2 | 1 500 - 9 100 |

|

| WM-L50/3 | 1 500 - 10 000 |

|

| Type | Rating (kW) | |

|---|---|---|

| WM-L10/1 | 75 - 405 |

|

| WM-L10/2 | 150 - 600 |

|

| WM-L10/3 | 250 - 800 |

|

| WM-L10/4 | 325 - 1 120 |

|

| WM-L20/1 | 400 - 1 400 |

|

| WM-L20/2 | 600 - 2 100 |

|

| WM-L20/3 | 800 - 2 600 |

|

| WM-L30/1 | 800 - 3 100 |

|

| WM-L30/2 | 900 - 4 100 |

|

| WM-L30/3 | 1 100 - 5 700 |

|

| WM-L50/1 | 1 200 - 8 000 |

|

| WM-L50/2 | 1 750 - 11 000 |

|

| WM-L50/3 | 1 750 - 12 000 |

|

| Type | Rating (kW) | |

|---|---|---|

| WM-S10/1 | 100 - 450 |

|

| WM-S10/2 | 175 - 700 |

|

| WM-S10/3 | 230 - 880 |

|

| WM-S10/4 | 300 - 1 120 |

|

| WM-S20/2 | 450 - 2 000 |

|

| WM-S20/3 | 700 - 2 450 |

|

| WM-S30/1 | 750 - 2 800 |

|

| WM-S30/2 | 900 - 3 700 |

|

| WM-S30/3 | 1 100 - 5 400 |

|

| WM-S50/1 | 1 600 - 7 400 |

|

| WM-S50/2 | 2 500 - 11 000 |

|

| WM-S50/3 | 2 500 - 12 000 |

|

| Type | Rating (kW) | |

|---|---|---|

| WM-GL20/2 | 200 - 1 450 |

|

| WM-GL20/3 | 350 - 2 000 |

|

| WM-GL30/1 | 450 - 3 700 |

|

| WM-GL30/2 | 500 - 4 500 |

|

| WM-GL30/3 | 500 - 5 000 |

|

| WM-GL50/0 | 1 000 - 7 500 |

|

| WM-GL50/1 | 1 000 - 8 300 |

|

| WM-GL50/2 | 1 100 - 11 000 |

|

| Typ | Rating (kW) | |

|---|---|---|

| WM-GL10/2 | 100 - 600 |

|

| WM-GL10/3 | 125 - 880 |

|

| WM-GL20/2 | 200 - 1 450 |

|

| WM-GL20/3 | 350 - 2 000 |

|

| WM-GL20/4 | 300 - 2 450 |

|

| WM-GL30/1 | 400 - 3 500 |

|

| WM-GL30/2 | 500 - 4 500 |

|

| WM-GL30/3 | 500 - 5 000 |

|

| WM-GL50/0 | 750 - 7 000 |

|

| WM-GL50/1 | 750 - 7 700 |

|

| WM-GL50/2 | 900 - 9 100 |

|

| WM-GL50/3 | 900 - 10 000 |

|

| Type | Rating (kW) | |

|---|---|---|

| WM-GL10/1 | 65 - 405 |

|

| WM-GL10/2 | 75 - 630 |

|

| WM-GL10/3 | 110 - 1 000 |

|

| WM-GL10/4 | 130 - 1 250 |

|

| WM-GL20/2 | 150 - 2 000 |

|

| WM-GL20/3 | 250 - 2 450 |

|

| WM-GL30/1 | 350 - 3 100 |

|

| WM-GL30/2 | 450 - 4 100 |

|

| WM-GL30/3 | 600 - 5 700 |

|

| WM-GL50/1 | 800 - 8 000 |

|

| WM-GL50/2 | 1 000 - 11 000 |

|

| WM-GL50/3 | 1 000 - 12 000 |

|

| Type | Rating (kW) | |

|---|---|---|

| WM-GS20/2 | 150 - 1 700 |

|

| WM-GS20/3 | 250 - 2 200 |

|

| WM-GS30/1 | 350 - 3 100 |

|

| WM-GS30/2 | 450 - 4 000 |

|

| WM-GS30/3 | 600 - 5 600 |

|

| WM-GS50/1 | 800 - 7 400 |

|

| WM-GS50/2 | 1 000 - 11 000 |

|

| WM-GS50/3 | 1 000 - 12 000 |

|